Choose Smarter Spend Management Today!

You’re constantly trying to manage spend, but procurement costs keep creeping up. Scattered purchases, inconsistent vendor pricing, and last-minute orders all push costs higher than planned. Too often, it feels like you're fixing bad decisions after the fact instead of controlling them from the start.

Procurement cost isn’t just the price you pay for goods. It includes everything from administrative overhead to delayed approvals and duplicate vendors. Reducing it isn’t about squeezing suppliers. It’s about building smarter processes that lock in value early and give you full visibility into how money moves.

In this blog, we’ll break down what procurement cost really includes, why it matters, and how to reduce it through practical, repeatable strategies without slowing down your business.

Key Takeaways:

Procurement cost includes more than the purchase price. It covers admin time, invoice processing, approvals, and inventory management.

Poor visibility, decentralised purchasing, and fragmented workflows quietly increase costs across departments.

Reducing procurement costs means standardising processes, consolidating vendors, and limiting off-contract spend.

Technology and automation help enforce policies, prevent errors, and identify cost-saving opportunities.

Sustainable savings come from continuous improvements, stronger supplier collaboration, and better data-driven decisions.

What is Procurement Cost?

Procurement cost refers to the total expense a business incurs to acquire goods or services from external suppliers. It includes more than just the purchase price. It also covers the administrative, logistical, and operational costs involved in the procure-to-pay (P2P) process.

Every step in procurement, from raising a purchase request to placing an order, receiving goods, processing invoices, and making payments, contributes to the overall cost. These expenses affect both profitability and efficiency, which is why tracking and managing them is essential for finance and procurement teams.

Procurement costs are typically divided into two categories:

Direct costs, which include the actual price of goods, freight charges, taxes, and duties

Indirect costs, such as employee time, procurement software usage, invoice processing, and quality inspections

Controlling procurement costs is not about cutting corners. It involves gaining full visibility into how money is spent, identifying inefficiencies, and building a system that delivers value throughout the entire purchasing process.

Types of Procurement Cost

Procurement costs can be grouped into direct and indirect categories. Understanding each type helps organisations identify savings opportunities more precisely.

1. Direct Procurement Costs

These are the easily identifiable costs tied to acquiring goods and services:

Purchase price: The actual amount paid to the supplier for goods or services

Shipping and freight: Transportation costs to move goods from the supplier to the warehouse

Customs duties and taxes: Any import/export charges or regional levies

Insurance: Charges for insuring goods in transit

Packaging: Costs for protective or branded packaging

2. Indirect Procurement Costs

These are the behind-the-scenes costs that accumulate throughout the procurement process:

Administrative costs: Time and resources spent on purchase orders, approvals, and vendor communication

Payment processing: Manual invoice reviews, approval delays, and duplicate payment errors

Supplier management: Time and effort spent onboarding vendors, maintaining contracts, or resolving disputes

Software and tools: Licensing fees for procurement platforms, ERPs, and related systems

Storage and handling: Costs related to warehousing, shelf life, and inventory holding

Quality inspections and rework: Time and materials required to check or fix delivered goods

By breaking down procurement costs into direct and indirect categories, teams can go beyond surface-level savings and target the root causes of spend inefficiencies.

Also Read: Understanding Procurement: Key Processes, Benefits

What Drives Procurement Costs Up?

Procurement costs can creep up silently when processes are reactive, fragmented, or misaligned with business goals. Understanding these cost drivers helps teams take proactive steps to control spend before it snowballs.

Here are the most common factors that drive procurement costs higher:

Decentralised Purchasing: When departments buy independently without coordination, it leads to duplicate orders, missed volume discounts, and vendor sprawl.

Maverick or Off-Contract Spending: Unauthorised purchases outside approved supplier lists or negotiated contracts often come with higher prices and hidden risks.

Poor Spend Visibility: Without a clear, centralised view of procurement data, it's hard to identify overspending, catch duplicate purchases, or benchmark pricing.

Inefficient Approval Workflows: Delays in approvals often lead to rushed or last-minute buys, where price becomes secondary to urgency.

Infrequent Contract Reviews: Letting agreements auto-renew without reviewing terms or comparing market rates locks you into outdated pricing and service levels.

Overreliance on Manual Processes: Spreadsheets, emails, and paper-based approvals are error-prone and time-consuming. They also make it difficult to enforce policy or track spend patterns.

Excess Inventory or Rush Orders: Poor demand forecasting leads to either overstocking (which ties up capital) or emergency purchases (which cost more).

Fragmented Supplier Base: Working with too many suppliers for similar items dilutes buying power and increases administrative overhead.

Why is Procurement Cost Reduction Necessary?

Procurement teams account for a significant share of business spending, often including raw materials, logistics, and administrative costs. When organisations reduce procurement costs, they increase profit, improve cash flow, and strengthen pricing power.

Rising procurement expenses without oversight can weaken financial health and threaten survival, especially during expansion or economic downturns. Companies that manage procurement spending maintain operational flexibility and avoid debt.

Lack of visibility into spending data makes it hard to spot inefficiencies or negotiate favourable terms. Procurement teams with precise data can cut unnecessary purchases and optimise supplier choices.

Fragmented procurement, like decentralised departments or outdated contracts, leads to duplicate purchases and missed volume pricing. Centralising orders and reviewing agreements restores efficiency and curbs overspending.

Procurement expenses include direct costs like unit price, shipping, and taxes, plus indirect costs such as storage, quality checks, and labour. Teams that track total costs grasp the full burden, giving them more savings paths.

Uncontrolled sourcing creates hidden risks, surprise rush orders, fraud, or price spikes. Organisations that control procurement protect against sudden cost surges and build resilience.

Procurement cost reduction helps create a smoother and adaptable organisation. Companies that monitor total spending, consolidate purchases, update contracts, and identify inefficiencies improve both profitability and stability.

Also Read: Best Procurement Tools and Resources in 2025

10 Strategies to Reduce Procurement Costs

Procurement cost reduction focuses on lowering total spend without sacrificing quality or performance. This step-by-step process involves analysing supplier contracts, enforcing approval workflows, consolidating purchases, improving data visibility, and gradually adopting tools like e-procurement systems.

Analyse and Optimise Spend

Spend analysis is the foundation of procurement cost reduction. This process clarifies where money is going, uncovers redundancies or overspending, and highlights high-impact areas for action.

Centralise Spend Data: Collect all purchase records into one clean, standardised system for a clear view of total spend.

Categorise and Tag: Group spend by vendor, cost centre, and item type to spot duplicates and off-contract purchases.

Spot Patterns and Outliers: Track pricing shifts, volume spikes, and unusual transactions to identify cost-saving opportunities.

Prioritise High-Impact Areas: Target categories and suppliers that account for the bulk of spend and offer the most savings.

Act on Insights: Renegotiate terms, consolidate vendors, and streamline purchases and approvals using digital tools.

Track Supplier Performance: Monitor delivery, pricing, and quality to adjust supplier mix based on results.

Repeat Regularly: Run this review quarterly to keep improving and catch new opportunities.

Eliminate Maverick and Non-Essential Spend

This process closes spending leaks by targeting unauthorised buys. Procurement teams regain control of tail and rogue spending by combining analysis, policy, software, training, and monitoring.

Spot Off-Contract Buys: Run spend checks to flag unauthorised vendors and informal purchases.

Use Approval Flows: Route all orders through purchase systems and block unapproved vendors.

Set Clear Rules: Share simple policies and train staff through quick sessions.

Make Buying Easier: Offer guided tools and pre-set catalogues to reduce friction.

Flag Issues Early: Use real-time data to catch and correct deviations quickly.

Track Results: Report off-contract savings as a share of total spending to show impact.

Stamping out maverick and unnecessary purchases yields two clear wins: cost savings and better contract terms. A disciplined approach, with approved channels, data-backed coaching, and friendly tools, ensures those savings endure.

Renegotiate and Review Contract Terms

This process starts with contract audits, followed by informed negotiation using market data. Adding flexible clauses, formalising agreements, and conducting ongoing reviews keeps procurement costs in check and reduces spending over time.

Review Existing Contracts: Check pricing, terms, and renewals. Flag overpriced or soon-to-expire agreements.

Benchmark Against Market: Gather external data on rates and service standards to guide negotiations.

Set Clear Goals: Define targets for pricing, volumes, payment terms, and fallback options.

Invite Competitive Bids: Use RFPs or reverse auctions to drive better offers and incentives.

Add Flexible Terms: Include clauses for pricing shifts, early exits, and performance-based rewards.

Document and Store: Record final terms and store them centrally for easy tracking.

Track Compliance: Monitor supplier performance and raise issues promptly.

Review Regularly: Revisit contracts every few months to compare against updated benchmarks.

Renegotiation and contract review drive visible cost reductions while maintaining quality. Careful planning, comparison, documentation, and supplier oversight prevent cost inflation and help capture fresh savings at each renewal.

Consolidate Suppliers and Purchases

Consolidation begins with spending data and ends with fewer, stronger supplier partnerships. That strategy cuts unit costs, lowers overhead, trims vendor burden, and improves buying terms.

Audit Spend Data: Clean and group purchases by category and vendor to spot overlaps and low-volume sources.

Centralised Buying: Route all orders through one system or team to cut duplication and reduce costs.

Reduce Vendor Count: Combine purchases under fewer suppliers to simplify coordination and gain better terms.

Invite Supplier Bids: Use RFPs or auctions to push for discounts on higher volumes.

Strengthen Vendor Ties: Focus on fewer, reliable partners to unlock rewards and faster issue resolution.

Review and Refine: Track spend metrics and adjust supplier mix every quarter.

Consolidating suppliers and purchases accelerates and scales procurement cost reduction. Procurement teams cut administrative hassle, gain pricing leverage, and sharpen vendor focus without sacrificing service.

Challenge Specifications and Standardise Requirements

Non-standard requests drive up costs and complexity. By aligning on common needs, creating standard specs, and bundling demand across teams, procurement reduces variation and unlocks volume discounts. Standardisation also streamlines approvals, simplifies inventory, and improves supplier reliability.

Use Strategic Sourcing and Category Management

By grouping spend into categories and assigning category leads, procurement teams gain better control and insight. Strategic sourcing events like RFPs and reverse auctions drive competition, while regular performance tracking ensures suppliers stay aligned with cost and quality targets. This structured approach keeps procurement agile and cost-efficient.

Use Technology and Automation

These tools move procurement from manual, fragmented processes to a digital chain, from purchase request to payment. They prevent mistakes, surface savings opportunities, and reduce inefficiencies..

Adopt P2P Tools: Automate approvals, orders, invoicing, and payments to speed up tasks and cut errors.

Use Analytics and AI: Clean and analyse data to track vendors, spot outliers, and suggest cost-saving options.

Set up Digital Catalogues: Let users pick from approved SKUs to cut off-contract purchases and standardise buys.

Run e-Auctions: Use real-time bidding to drive down supplier prices quickly.

Automate Invoice Matching: Digitally match POs to invoices to reduce admin work and avoid double payments.

Track Supplier Metrics: Use dashboards to monitor cost, delivery, and quality and share feedback.

Scale in Phases: Start with ordering and invoicing; add advanced tools as teams gain comfort.

Innovative technology use injects discipline and speed into procurement.

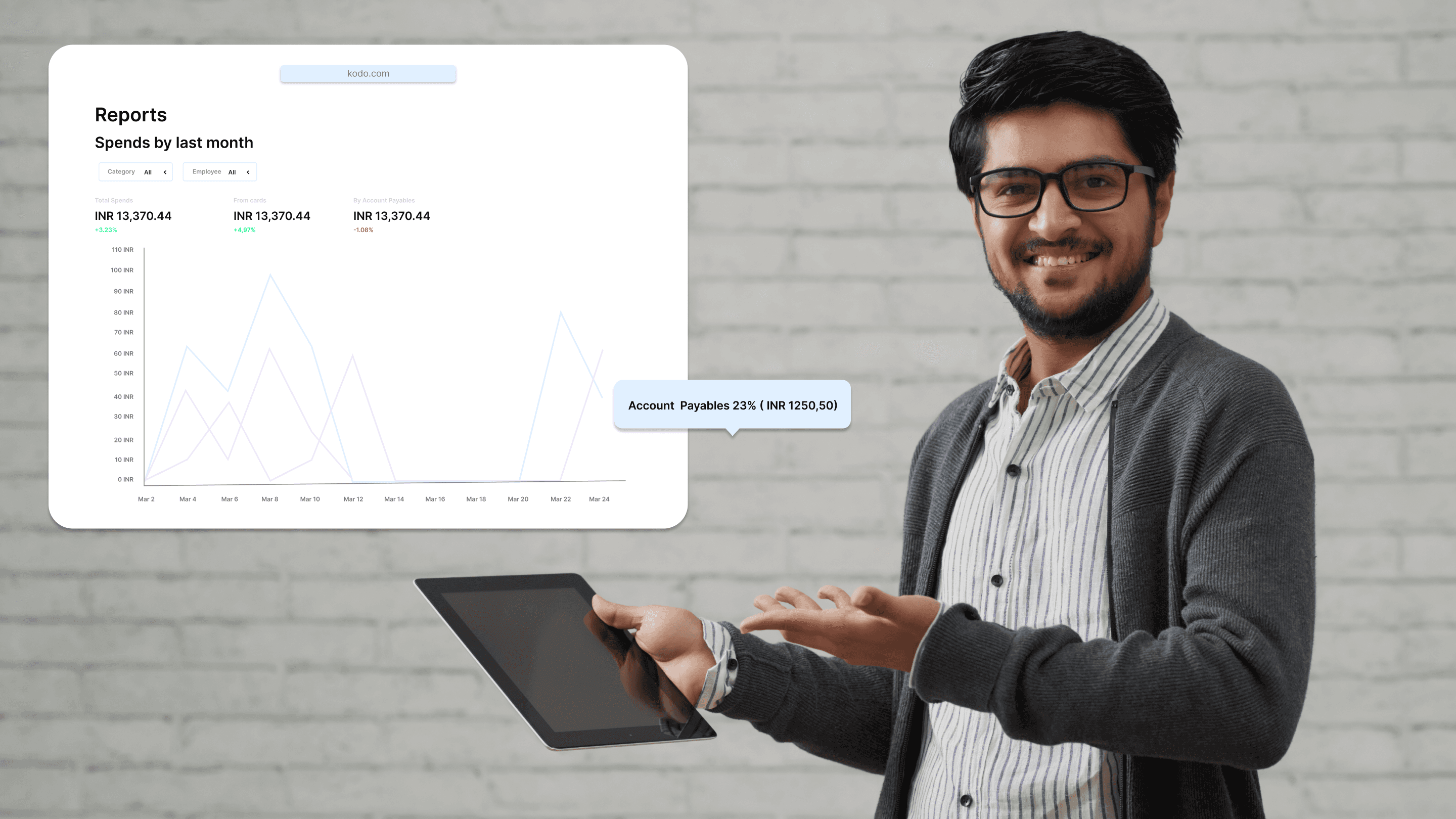

Kodo helps reduce procurement costs by centralising orders and offering complete spend visibility. With built-in workflows and real-time data, teams can track every purchase, simplify approvals, and negotiate better rates in one platform.

Optimise Delivery and Inventory Management

Procurement teams cut storage, dead stock, and transport costs by forecasting demand, setting ideal order sizes, using consistent ordering, reducing stock buffers, auditing inventory, and optimising shipment paths.

Forecast Demand: Use past data and trends to predict needs. Helps cut excess stock and urgent buys.

Set Order Size with EOQ: Use EOQ to balance ordering and storage costs for better inventory planning.

Adopt JIT or Vendor-Managed Stock: Order only when needed or let suppliers handle inventory to reduce storage costs and avoid overstocking.

Classify and Audit Stock: Use ABC or FSN methods to focus on key items. Clear out slow movers with regular checks.

Improve Shipping and Packaging: Group shipments, pick efficient transport, and pack to save space and cost.

Track Inventory Metrics: Monitor DIO, turnover, and costs. Use models to find stock issues or delays.

Smart delivery and inventory management drive procurement cost reduction. Teams that forecast accurately, order with precision, and fine-tune supply flows free up capital, avoid overstocking, and lower logistics costs.

Strengthen Supplier Relationships and Collaborate

Strong supplier partnerships often lead to better pricing, faster issue resolution, and improved service. Teams that share forecasts, align incentives, and run joint workshops with key vendors unlock savings that go beyond traditional negotiations. Collaboration builds trust, reduces risk, and delivers long-term value on both sides.

Also read: Vendor Relations: The Hidden Benefit of Faster Payments

Promote a Culture of Continuous Improvement

Procurement cost savings don’t just come from big projects or tech upgrades. They often stem from consistent, everyday improvements. When teams are encouraged to share small ideas regularly, even quick process tweaks can add up, especially from the people doing the work.

To make this culture stick, train teams on root-cause analysis, negotiation tactics, and data interpretation so they can spot savings themselves. Share success stories openly to build momentum across departments. And don’t stop at internal teams; bring suppliers into the process through joint planning sessions and improvement incentives. When everyone is invested in doing things better, the savings become repeatable, not accidental.

By combining quick tactical steps with longer-term changes in process and technology, businesses can reduce waste, strengthen supplier relationships, and improve margins sustainably.

How Kodo Helps You Cut Procurement Costs

All the strategies you've just read, from eliminating maverick spend to consolidating vendors and automating workflows, are easier said than done without the right system in place. That’s where Kodo comes in.

Kodo gives finance and procurement teams full visibility and control over every step of the procurement process without creating friction for business users. It standardises how requests are made, how vendors are selected, and how payments are approved, all while tracking spend in real time.

Here’s how Kodo supports smarter procurement cost management:

Purchase Order: Kodo supports custom workflows that follow your internal policies by amount, category, or department, preventing inflated or unnecessary orders from slipping through.

Purchase Request: Kodo lets you standardise request forms and approvals by department, spend limit, or vendor. This reduces maverick purchases and gives finance teams upfront control over spending.

Vendor Management: Kodo helps control payout timing and accuracy with scheduled or one-time payments, approval workflows, audit trails, and real-time status updates, reducing errors and improving cash flow visibility.

Cross-Platform Integration: Bi-directional syncing with ERPs like Tally, Zoho, SAP, and Oracle means fewer errors and faster reconciliation. Purchase orders, invoices, and receipts move between systems without manual re-entry, cutting admin time and reducing the cost of corrections.

Invoice Management: With two-way and three-way matching, Kodo flags mismatches before payment. This helps eliminate overpayments, detect duplicates, and track discount opportunities often missed in manual reviews.

With real-time tracking, clean audit trails, and better procurement discipline across teams, Kodo helps companies uncover and stop cost leakages across the intake-to-pay cycle without changing how people work.

Wrapping Up

You’ve seen how quickly procurement costs can add up; missed discounts, rushed purchases, bloated vendor lists, and poor visibility all chip away at your margins. Cutting costs isn’t just about spending less. It’s about making smarter choices with the money already going out the door.

From tightening your supplier base to improving how your team places orders, every minor fix adds up. You don’t need a complete overhaul. You need to take the first step, stay consistent, and keep looking for the next place to trim waste. The savings will follow.

Kodo helps you cut procurement costs by giving your team tighter control over how money moves. With real-time budget tracking and order approvals, teams spot overspending before it happens, not after. Every minor fix adds up, and Kodo keeps that momentum going. Book a demo to get started today.

FAQs

Can standardising product specifications really lead to measurable savings?

Yes. Standardisation reduces variety across purchases, which increases order volume for fewer SKUs. This simplifies inventory management and gives you better pricing power with suppliers due to higher consolidated demand.How do internal purchase approvals impact cost reduction?

Lengthy or unclear approval processes delay orders, which can lead to urgent, last-minute buying, usually at higher prices. Streamlined approvals cut indirect costs by reducing delays, rework, and rush fees.What’s the hidden cost of not regularly reviewing supplier contracts?

Outdated contracts often carry legacy pricing, unnecessary services, or outdated clauses that no longer reflect market rates. Regular reviews uncover these gaps and create opportunities to renegotiate or switch providers.Do e-procurement tools reduce costs beyond just automation?

Yes. Beyond time savings, these tools help uncover maverick spending, track price trends, and flag duplicate purchases. With better data, procurement teams negotiate with more confidence and avoid overbuying.Can supplier relationship management influence cost savings?

Absolutely. Strong relationships often result in priority service, early access to discounts, and flexible payment terms. It's about the lowest quote, long-term value and reliability.