Choose Smarter Spend Management Today!

Introduction

Procurement doesn’t always go according to plan. Prices spike without warning, suppliers miss deadlines, and contracts fall through. When these things happen, they don’t just slow you down; they cost real money, time, and trust.

Organisations typically manage supplier relationships, but average annual losses from supplier disruptions hit around around ₹15 billion per company. Most teams feel the pressure of juggling too many unknowns with too little visibility. Risk gets pushed to the side until it’s too late. And by then, it’s damage control.

This blog explains procurement risk management, how to get ahead of those problems, take practical steps to spot risks early, avoid surprises, and bring more stability to your procurement process, even when things change quickly.

Key Takeaways

Regular analysis of spending patterns and supplier data helps spot vulnerabilities, such as overdependence on a single vendor or rising costs, before they affect budgets or delivery timelines.

Tracking supplier performance, conducting audits, and maintaining open communication helps identify delivery issues, compliance gaps, or financial instability before they escalate.

Clear contract terms, insurance, hedging strategies, and performance bonds distribute risk more evenly and protect organisations from sudden cost spikes or supplier defaults.

Educating teams on fraud signals, quality standards, and cyber threats, combined with digital systems that automate and document workflows, lowers manual errors and strengthens risk response.

Stock buffers, alternate sourcing plans, and crisis protocols reduce downtime when events like natural disasters, geopolitical shifts, or transport delays interrupt normal operations.

What is Procurement Risk?

Procurement risk refers to any event or condition that threatens an organisation’s ability to purchase goods or services in a timely, cost-efficient, high-quality, and compliant manner. These threats can arise from internal missteps or external forces beyond a company’s control.

Why is Procurement Risk Management Necessary?

Procurement risk management addresses threats that could derail sourcing and delivery, ranging from financial surprises and supply disruptions to quality failures, legal exposure, fraud, and reputational damage.

These risks overlap: a supplier’s economic troubles might lead to quality issues and trigger compliance failures. Tracking indicators, like supplier audits, contract terms, and market trends, enables preemptive action.

Cost Stability

Unexpected price changes can undermine budgets from currency fluctuations, raw-material spikes, or hidden fees. Proactive risk management provides early warning and mitigation, helping to safeguard profit margins.

Operational Continuity

Interruptions in the supply chain caused by natural disasters, geopolitical events, single-supplier failures, or pandemics can halt production and delay deliveries. Risk planning reduces downtime and prevents losses.

Quality Assurance

A breakdown in supplier quality control, from unclear specifications, inexperienced partners, or inadequate testing, can lead to defective inputs, costly delays, and recalls. Identifying and addressing these risks keeps standards intact.

Compliance and Ethics

Contracts with vague terms or relationships with non-compliant suppliers carry the threat of fines, legal disputes, and brand damage. Managing procurement risk includes supplier due diligence, tailored contract terms, and monitoring for ethical lapses such as corruption or labour violations.

Supplier Stability and Relationships

If a key supplier fails due to insolvency, takeover, or sudden operational problems, the impact cascades through production. Monitoring financial health, performance, and ethical practises supports a reliable network and fosters trust.

Brand Value and Client Trust

Customers and stakeholders increasingly favour companies that manage risks related to sustainability, ethics, and supply consistency. Companies demonstrating transparency in procurement earn stronger loyalty and a willingness to pay premiums.

Also Read: Kodo: Intake-to-Pay and Payments Simplified!

Strong risk discipline involves assessing suppliers, reviewing contracts, deploying technology and audits, and maintaining backup plans to ensure consistent and responsible procurement amid market changes and crises.

Knowing the importance is one part. Seeing how the process plays out in real operations is equally valid.

How Procurement Risk Management Works?

Procurement risk management involves a systematic cycle, identifying, assessing, categorising risks; designing and implementing responses; monitoring results; and learning from outcomes, using data, insights, and tools to proactively manage exposure. A structured process breaks risk management into clear, actionable stages:

Risk Identification

Map all potential threats that could disrupt procurement, supplier failure, quality issues, market turbulence, cybersecurity vulnerabilities, or regulatory shifts. Use root-cause workshops, supplier performance data, historical incidents, and market intelligence. This stage must be ongoing and updated as new risks emerge.

Risk Assessment & Prioritisation

Evaluate likelihood and impact using risk matrices or scoring methods for each risk. Engage cross-functional teams, procurement, finance, and legal, to rank risks by severity. This will guide focus to the most damaging threats.

Assign Risk Categories & Context

Group risks into logical buckets (e.g., supplier, market, contractual, cyber) to target response tactics. Align supply segmentation (e.g., via the Kraljic matrix) with procurement importance and market complexity.

Develop Risk Responses

Evaluate each risk’s potential effect on project success and costs, then select response strategies tailored to the risk’s nature and priority.

Avoidance: Opt out of risky suppliers or volatile markets.

Reduction: Vet suppliers, add quality checks, hedge commodity exposures.

Transfer: Build risks into contracts, insurance, or shared agreements.

Acceptance: Monitor minor risks with minimal impact.

Execution of Mitigation Measures

Turn plans into action:

Broaden the supplier base for critical parts.

Negotiate clear contract clauses, delivery terms, penalties, and dispute mechanisms.

Use e‑procurement tools with audit logs, approvals, and cybersecurity protections.

Conduct audits, supplier reviews, site visits, and scorecards.

Monitoring & Review

Continuously track risk indicators, supplier health, market changes, and contract compliance. Use dashboards, periodic audits, stakeholder feedback, and scenario drills to detect shifts early.

Learning & Iteration

Review outcomes when risks materialise or mitigation plans are tested. Document lessons, refine scoring methods, update contracts, and strengthen technology and training. This promotes resilience over time.

Also Read: Accounts Payable Automation

Procurement risk management continuously progresses as organisations identify, prioritise, treat, and monitor risks to build sourcing reliability.

Identifying the common risk areas that tend to cause the most trouble if left unchecked can help prepare better.

Which Procurement Risks You Should Look Out For?

Procurement teams face many hazards that can cause financial loss, disrupt operations, or damage reputation. Here's a refined breakdown of the most relevant risks and what makes each stand out:

Supplier Risk

This includes delivery delays, production failures, quality lapses, insolvency, and acquisitions of suppliers. It often stems from over-reliance on one vendor; diversifying suppliers and maintaining backup options helps reduce exposure.

Quality & Specification Risk

Failure to establish clear product or service specifications can lead to defects, rework, recalls or compliance breaches. Without supplier audits or acceptance testing, oversight gaps widen.

Price & Market Risk

Procurement budgets can collapse under volatile raw-material prices, currency shifts, or hidden charges. Inaccurate forecasting worsens exposure to market swings and budget overruns.

Supply Chain Disruption

Unexpected events, natural disasters, political unrest, and pandemics can sever supply lines at any tier. This includes logistics delays and blackout zones in tier‑2 or tier‑3 networks.

Compliance & Contract Risk

Contracts lacking detail or burdening one party with undue risk often result in disputes, fines, or legal exposure. Failure to include data protection, labour, or ESG clauses increases vulnerability.

Financial & Credit Risk

Vendor insolvency, weak balance sheets, or lack of payment transparency create exposure. Continuous monitoring of supplier financial health and creditworthiness is essential.

Fraud & Ethical Risk

Procurement is exposed to fake suppliers, invoice padding, kickbacks, bid collusion, or corruption. Weak approval systems and manual workflows amplify vulnerability.

Operational & Logistical Risk

Includes delays from transportation breakdowns, natural disasters, or inefficient internal procedures. It is often worsened by siloed systems and outdated processes.

Data & Cybersecurity Risk

Procurement platforms hold contracts, pricing, and intellectual property. Cyberattacks, data breaches, or insider build-ups can cause financial and reputational fallout.

Operational & Process Risk

Manual or outdated workflows lead to lost orders, duplicate purchases, inaccurate data, and overspending. Outdated P2P systems can compound these errors.

Demand & ESG Risk

Misread demand causes stock imbalances; supplier non-adherence to ESG norms can implicate the buying firm in reputational harm or regulatory audits. Scope 3 emissions, sustainability non-compliance or greenwashing can trigger stakeholder scrutiny.

A strong procurement risk approach tracks supplier stability, market shifts, legal compliance, process integrity, finances, ethics, cyber threats, demand accuracy, and sustainability commitments.

Kodo brings this visibility to life, offering one connected platform across procurement and finance. With real-time approvals, automated vendor payments, and synced workflows, teams move faster with fewer surprises. Every request, order, and payment is traceable, freeing up hours and reducing budget friction as companies grow.

Considering those factors, you can start shaping an approach that will keep your procurement activities on solid ground.

What are the Strategies for Effective Procurement Risk Management?

These strategies complement one another. Start with proactive assessments to identify risks, use due diligence and contracts to set clear limits, reinforce operations through supplier monitoring and backup plans, and enhance agility with training and technology.

Together, they reduce vulnerability across cost, compliance, resilience, fraud, ESG, and tech exposure. A well-rounded approach combines targeted tactics and system-wide foundations:

Regular Spend & Risk Assessments

Keep procurement risk profiles current. Analyse spending patterns to spot supplier concentration, budget risks, and hidden dependencies. Update risk ratings based on market trends, supplier health, and geopolitical signals.

Ongoing Supplier Oversight

Track KPIs, delivery rate, defects, responsiveness, and compliance. Use periodic audits and real-time dashboards. Trigger corrective measures early to prevent escalation.

Inventory, Contingency & Crisis Planning

Maintain buffer stock for essential items and develop contingency sourcing plans. Develop emergency response playbooks and test via tabletop exercises.

Spread Risk via Contracts, Insurance & Hedging

Shift exposure by including performance bonds, pricing hedges, insurance, shared-risk terms, or purchase instruments that spread risk across parties.

Raise Awareness & Train Teams

Make risk ownership everyone’s job. Share updates, conduct incident drills, and train staff in risk signals, contract requirements, fraud spotting, and cyber hygiene.

Offer Transparency and Collaboration

Enable audit trails and dashboards to share insights with stakeholders. Open dialogue with suppliers and internal teams fosters quicker issue resolution.

Apply Tech & Analytics

Leverage e‑procurement platforms, AI tools, blockchain, and data analytics to flag early warning signs: spend anomalies, cyber threats, performance dips, and ESG exposure.

Risk management is a continuing practice. When integrated through spending data, contract design, supplier controls, backup provisions, awareness, and innovative technology, procurement can stay budget-safe, agile under disruption, trustworthy to stakeholders, and resilient to threats.

Of course, no strategy works without action. Here’s how to respond when risks start to show up.

How to Mitigate Procurement Risks?

Mitigation depends on combining structural safeguards (dual sourcing, contracts, safety stock), real-time oversight (performance metrics, audits), and systemic supports (technology, training, cybersecurity, financial tools).

Each component addresses risk dimensions: operational, economic, ethical, legal, market, and technical. Targeted mitigation begins once risks are identified and ranked. These steps help reduce the likelihood and impact of procurement setbacks:

Supplier Diversification & Segmentation

Introduce multiple sources, preferably spread across different regions, to avoid overreliance on a single vendor. Segment suppliers by their importance and risk; critical vendors need stronger oversight.

Rigorous Due Diligence & Onboarding

Assess a potential supplier’s financial health, quality systems, ethics, and compliance. This should include site visits, audits, and background checks targeting bribery, labour, and environmental risks.

Smart Contracting

Create contracts that assign delivery schedules, quality standards, force majeure, variable pricing, performance bonds, audit rights, ESG clauses, and clear dispute paths. Keep contracts current with market and regulatory changes.

Performance Monitoring & Regular Audits

Track KPIs like delivery adherence, defect rates, and contract compliance. Schedule audits and performance reviews to detect quality or ethical issues early.

Risk Sharing & Financial Instruments

Use insurance, hedging for commodity/currency exposure, performance bonds, or shared-cost provisions to shift financial risk away from your organisation.

Procurement Technology & Analytics

Adopt e‑procurement systems that offer digital records, automated workflows, real-time alerts, and spend analytics. Consider machine learning and AI for supplier risk profiling.

Cybersecurity & Data Protection

Enforcing multi-factor authentication, encryption, firewalls, vendor cybersecurity standards, and regular penetration testing can protect procurement data.

Standardised Processes & Team Training

Define procurement workflows for vendor evaluation, approvals, contract reviews, and audits. Train staff to spot fraud signals, legal vulnerabilities, quality gaps, and cyber threats.

Collaborative Supplier Management

Nurture supplier relationships through open dialogue, shared KPIs, joint improvement programs, and mutual escalation processes. Early detection of issues is enabled by trust and routine engagement.

Mitigation isn’t a single-step fix but a coordinated effort involving multiple tactics. Procurement functions can reduce surprises, control costs, maintain supply flow, and protect reputation by combining redundancy, safeguards, oversight, procedural rigour, and continuous monitoring.

This built-in resilience helps procurement stand firm when disruptions arise. Managing risks manually can slow things down. Kodo helps ease this process with tools built for modern teams.

How Can Kodo Help in Effective Procurement Risk Management?

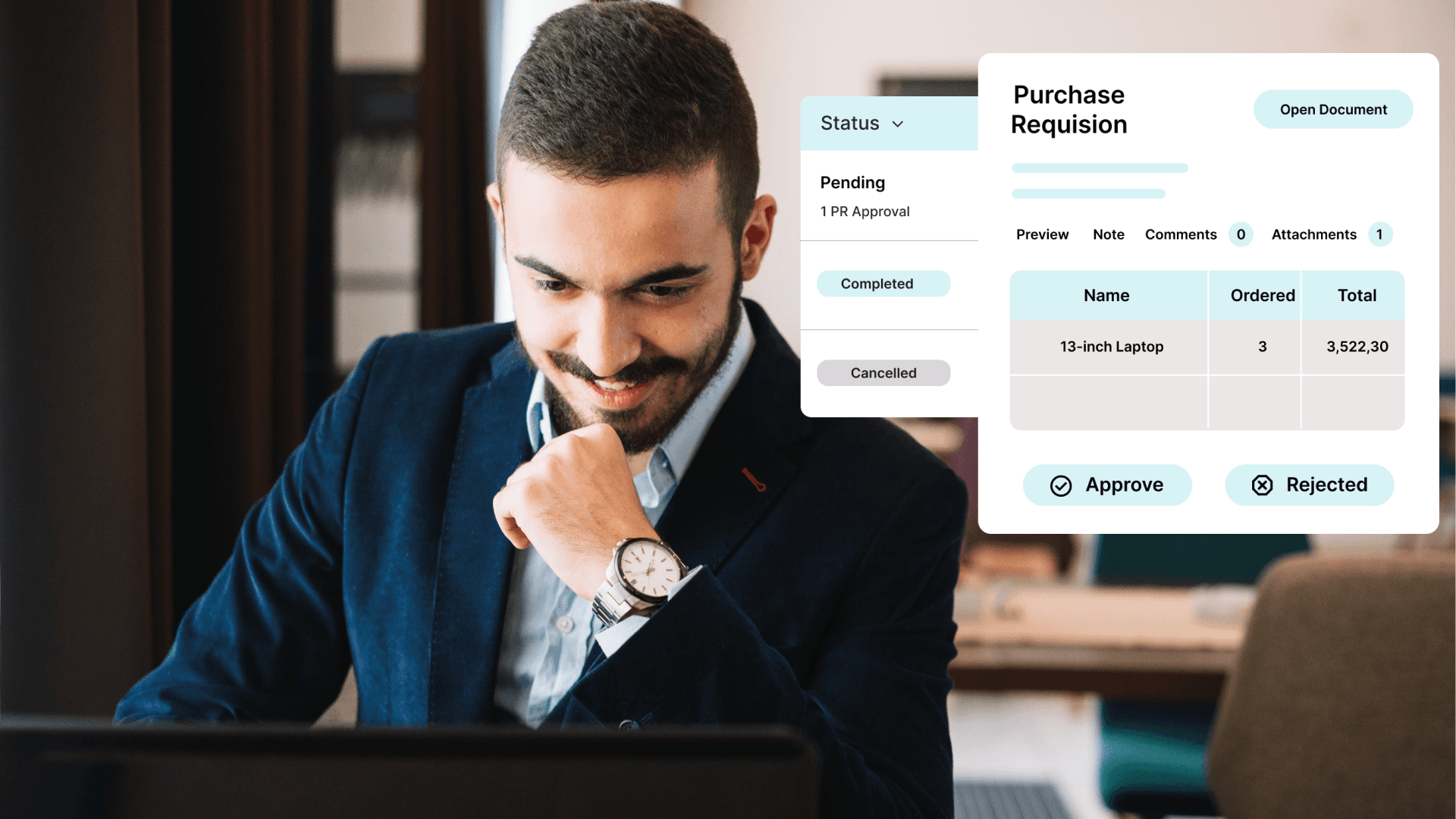

Kodo simplifies invoice payments by connecting approvals, documents, and payouts in one clean flow.

Invoice Management: Invoices can be uploaded and matched against approved POs or earlier quotes. Kodo flags mismatches early, reducing last-minute escalations and manual cleanup.

Purchase Request: Every invoice starts with an explicit, documented request. Teams can raise purchase requests tied to expected spending, vendors, and quote history so finance has complete visibility from the start, with no surprises when the invoice arrives.

Purchase Order: Once requests are approved, Kodo lets you create purchase orders without jumping between tools. These POs link back to the original request and vendor selection, keeping everything traceable and consistent.

Vendor Payments: After complete approvals, payments can be scheduled or automated based on the agreed-upon terms. Each payment stays connected to its invoice and sourcing history, making audits and reviews easier.

Cross-Platform Integration: Kodo syncs with your finance tools so purchase data, invoice statuses, and payment records flow across systems without repeat entry or tracking gaps.

Kodo helps finance and procurement teams process invoices with less friction, fewer delays, and better visibility across every step.

Conclusion

Procurement comes with its fair share of uncertainty, price jumps, supply disruptions, and contract gaps. While not every risk can be avoided, many can be spotted early and handled before they turn into bigger problems with the help of procurement risk management. What helps most is having a plan that’s easy to follow and fits how your team works.

It’s not something built for a perfect world, but one that accounts for real-life delays, unexpected costs, and sudden changes. The goal isn’t to eliminate risk. It’s to stay ready, respond faster, and keep things moving when plans shift because they always do.

That’s where Kodo fits in. It was built for teams that want to move faster without losing grip on the details. Over 2000+ companies use Kodo to reduce approval cycles, reduce invoice mismatches, and track vendor payments without manual follow-ups.

From ₹2,000 purchases to multi-figure orders, everything stays visible, connected, and easy to act on. Whether you're handling five purchase requests a week or fifty a day, Kodo gives teams a more straightforward way to manage the process from request to payment. Book a demo with Kodo today.

FAQs

How can procurement teams detect risks hidden in tier-2 and tier-3 suppliers?

Most companies focus on direct suppliers, but disruptions often come from deeper tiers. Asking tier-1 suppliers to disclose their key vendors and conducting periodic risk audits across the extended supply chain can uncover blind spots.What role does ESG compliance play in procurement risk today?

Environmental, social, and governance (ESG) risks can lead to reputational damage or regulatory fines. Tracking supplier ESG scores or integrating ESG clauses into contracts helps mitigate risks that don’t show up in price or delivery metrics.Can payment terms be used to manage procurement risk?

Yes. Structuring payment terms based on delivery reliability or quality benchmarks allows companies to hold back funds if suppliers underperform, providing a financial buffer while limiting exposure.How can internal procurement policies themselves become a risk?

Overly rigid procurement rules can slow response times during disruptions. Periodic reviews help spot bottlenecks or approval delays that increase exposure during crises or urgent sourcing needs.Is single-sourcing ever a good risk strategy?

While often seen as risky, single-sourcing can be effective when paired with strong contracts, clear SLAs, and business continuity clauses. In niche markets, it can even reduce complexity.